Analyse -> Model -> Simulate -> Review -> Improve

We use advanced simulation and analysis tools and techniques to explore options, optimise your product's design and ensure it is within specifications. The following extensive examples elucidate our simulation capabilities.

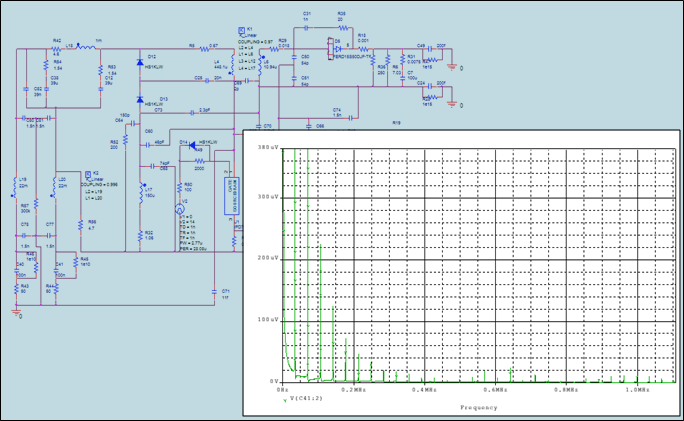

PSpice Circuit Simulation

Accurately predicting component performance in complex circuit designs prevents costly and time-consuming board re-spins and re-testing for regulatory compliance.

We are one of only a handful of electronics engineering enterprises in Australia proficient in the use of Cadence Design Systems advanced OrCAD® PSpice™ SPICE simulation and analysis tools.

With PSpice we're able to undertake advanced circuit characterisation, which allows us to optimise the selection of components that offer the most appropriate mix of performance, reliability, longevity and price.

This example shows the how the performance of a circuit is modified to meet specified parameters via adding specific components.

Signal Integrity Simulation

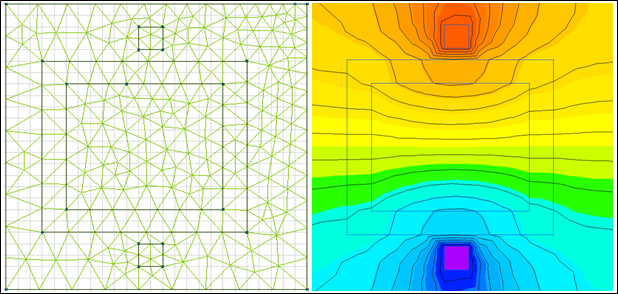

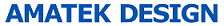

Accurately predicting PCB electrical and signal performance in complex, multi-layer PCBs is proven to reduce the need for time-consuming and costly board re-spins. It's also a proven means of optimising PCB layouts to meet regulatory compliance for Electromagnetic Compatibility (EMC) and electrical safety.

Amatek is one of only a handful of electronics engineering enterprises in Australia proficient in the use advanced signal integrity modelling tools, including Cadence Design Systems OrCAD® Sigrity™.

See an example of a multi-layer PCB being analysed in real-time using Cadence's advanced Sigrity SI (Signal Integrity) software.

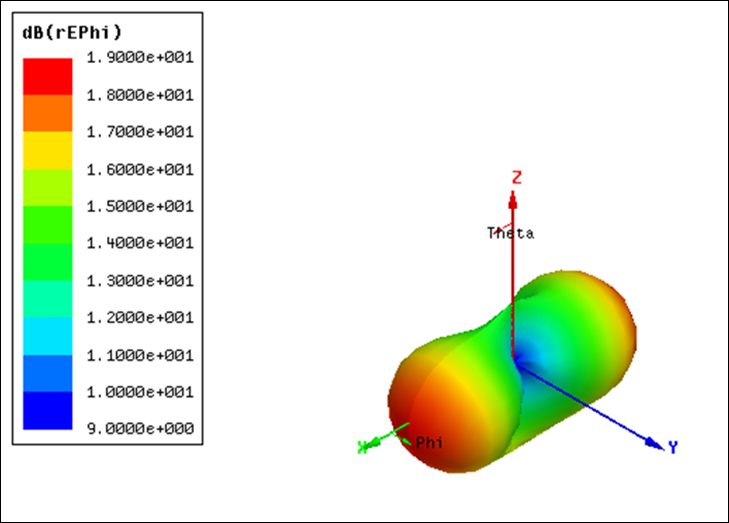

RF Simulation

The control of Radio Frequency (RF) or Electromagnetic (EM) emissions in electronics can be challenging, especially when a design is a mix of sub-systems that need protection from radiated energy, such as signal pathways on a PCB, as compared to sub-systems that need optimal emissions such as WiFi or Bluetooth antennas.

Amatek uses 3D EM simulation tools to optimise designs. Our expertise in developing highly reliable, robust and efficient WiFi, Bluetooth, BLE, Near Field Communications (NFC) RF systems is evident in the range of highly successful products we've helped customers get to market.

Whether wirelessly connected AgTech control and monitoring products that must operate reliably in harsh, remote areas, home automation systems requiring reliable cloud connections via WiFi in order to or medical monitoring devices that need reliable communications, Amatek is proficient in the use of simulation tools to optimise RF product designs.

This example shows a newly developed antenna module being simulated to ensure that the radiation pattern and signal gain matched the requirements of the RF module used.

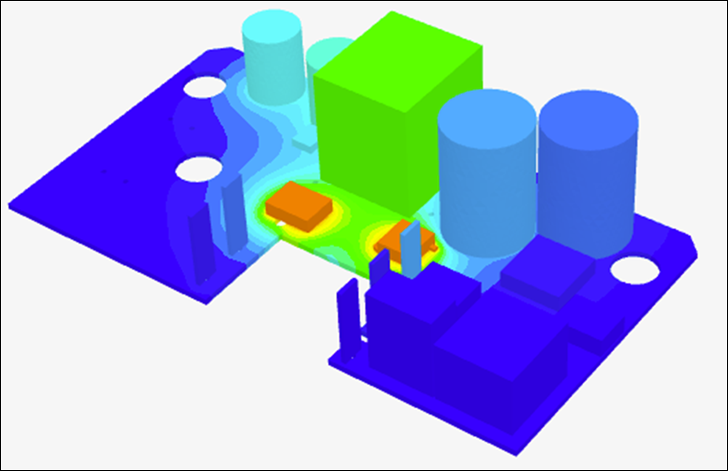

Thermal Simulation

Thermal management is an issue often overlooked by designers. However, with designs involving ever smaller packaged more tightly together on PCBs, and main processors that operate at higher speeds, there may be a need to model PCBs, power supplies andr even entire assembled products before they go to prototyping.

This is done to ensure there is appropriate heat dissipation an hence no overheating, which can lead to shortened product lifespans and even catastrophic failures.

This example shows a SimScale simulation to determine the thermal profile inside an enclosure. The objective was to optimise the determine whether any component exceeded its thermal limits when in operation.

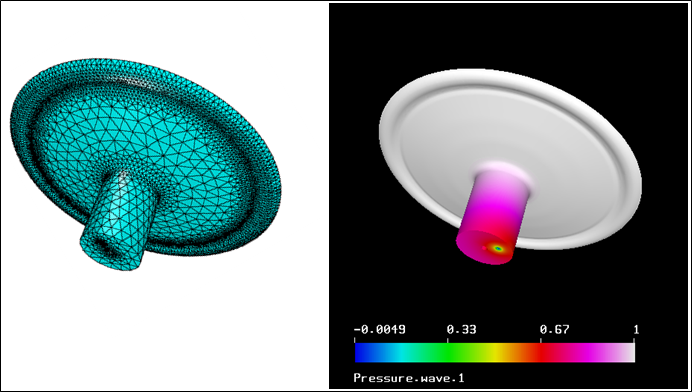

Acoustic Simulation

Whether its to reduce the noise produced when operating, or to optimise an acoustic device such as a speaker or a microphone, acoustic modelling may be required to develop a functional electronic or mechanical system.

As with other simulation techniques, building virtual models and simulating their behaviours to optimise a design can help Amatek shorten times taken to prototype, validate and manufacture client's products.

This example shows the acoustic behaviour of a microphone feedhorn. The simulation objective was to optimise the diameter of the depressurisation hole beneath the microphone to obtain a clear sound recording.

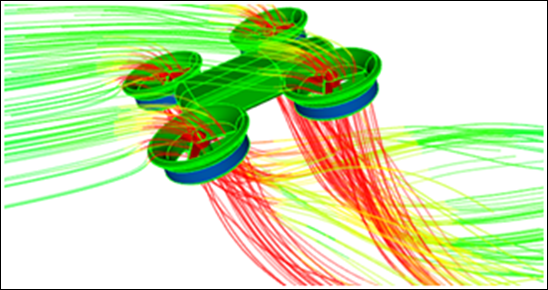

Computational Fluid Dynamic (CFD) Simulation

CFD is a modelling technique often required to develop complex mechanical systems, especially those with moving parts. CFD is an especially valuable simulation technique when modelling and analysing turbulent flows, such as those inherent in devices such as propeller that creates both turbulent flows and generates considerable amounts of heat.

Amatek can utilise CFD in the design, simulation, analysis and optimisation of complex devices, such as electric propulsion systems for autonomous drones.

This example shows CFD modelling and analysis of air flow into and out of a ducted propellor shroud, with analysis revealing differences in the thrust achievable using slight modifications to the basic design.

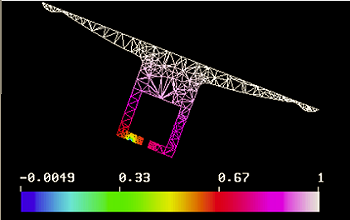

ESD Simulation

Simulating Electrostatic Discharge (ESD) in electronics is required where devices are susceptible to damage from over-voltage spikes. This is especially the case in low-power devices where smaller, closer tracks on the PCB increase the potential for damage and even catastrophic failure.

ESD simulation helps Amatek optimise designs by identify areas requiring enhanced protection, or require that the PCB layout be modified.

This example shows modelling of the electrical potential distribution inside a floursecent tube.