Inspired Designs That Engage Customers

Amatek provides value at every stage of the product development lifecycle:

- Early stage concept evaluation.

- Technology and engineering risk analysis and product research.

- Full product design and development, electronics, simulation, software and mechanicals.

- Compliance program specification and management.

- Manufacturing support and on-going design update services.

Our design approach is based on many years of experience in technology product engineering that clients appreciate and on which they can build their brand value and commercial success.

Services

- Whole of product lifecycle support

- Concept evaluation and technology research

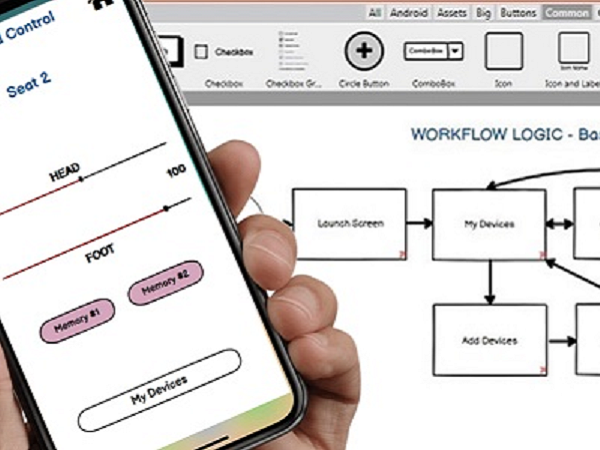

- Detailed analog, digital, low power and RF electronics design

- Design simulations

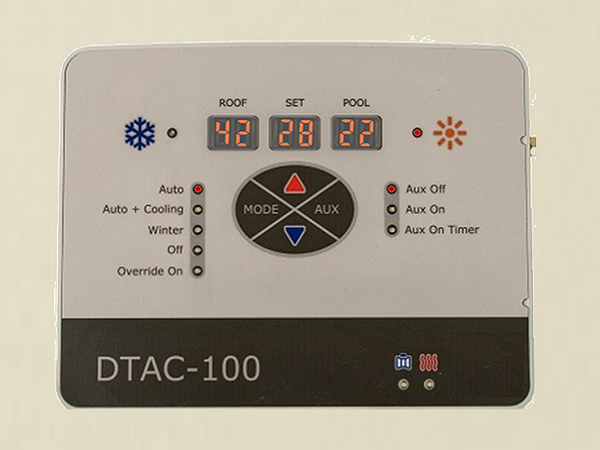

- Application software development

- UI/UX design and development

- Industrial and mechatronics design

- Systems integration

- Regulatory compliance

- Product re-engineering for cost reductions and parts availability

- Design maintenance and updates

- Commercialisation planning and assistance

Expertise

- IoT (IIoT, IoMT)

- AgTech

- MedTech

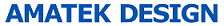

- Automation and Control Systems

- Home Automation Systems

- Power Management and Energy Saving

- Broadcast and Audio

- Defence and Aerospace

- Access Control, Biometrics and Security

- Point-Of-Sale (POS) Displays and Signage

- LED and Induction Lighting

- Firesafety

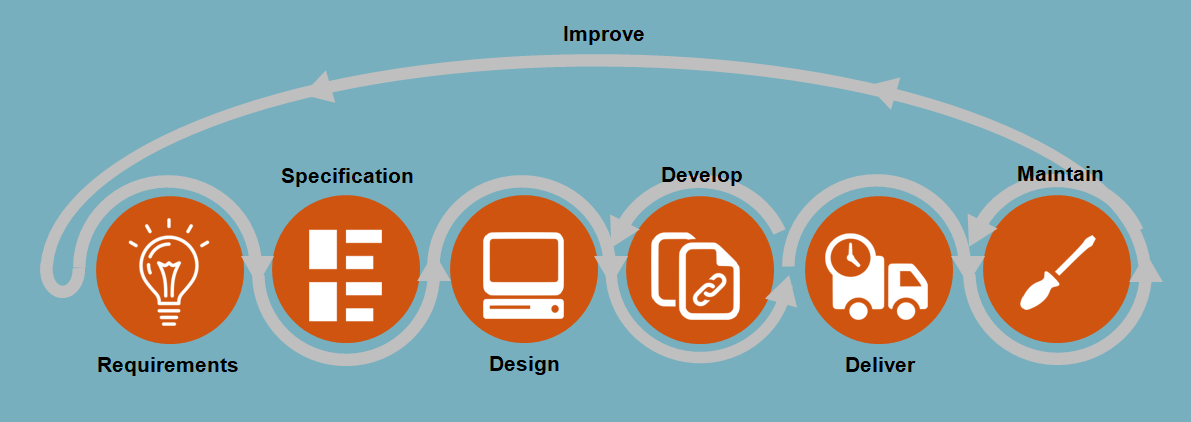

Product Development Lifecycle

Requirements

We will document the required outcomes of your project addressing:

- Overarching requirements of the product.

- Regulatory compliance requirements in the product target markets.

Specification

We will develop specifications that defines how we will achieve those outcomes, covering:

- Embedded system specifications including architectures, processor capacity, and critical components.

- Mechanical specifications, such as enclosure materials, dimensions and IP ratings.

Design + Develop

Once requirements and specifications are agreed, the engineering design and development begins, with the objective being to create either:

- A technology research exercise to validate A proof-of-concept prototype, or

- Or a fully functional, production-ready, sub-system or finished product

We'll then undertake:

- Schematic and PCB design and development

- Industrial and mechatronic systems design

- Software development

- Prototype procurement and construction

- Prototype verification testing

- Regulatory compliance testing

- Field trials and user acceptance testing

- Pre-production refinement and optimisation for production

- Production test specification and test jig design

Deliver + Maintain + Improve

Once a product has been approved for manufacture, we can undertake the following:

- Manufacturing documentation package development

- Introduction to manufacturing, including documentation handover and production training

- Manufacturing support including component purchasing assistance

- Production test jig supply and training

The handover to production doesn't mean the end of our involvement as we can also provide the following support services:

- Product maintenance including BOM reviews and updates

- Iterative design improvements and updates

- Software maintenance

- Product redesign